Titanium Cnc Parts

Brand Runxin Machinery

Product origin LiaoNing, China

Delivery time 1 month

Supply capacity Monthly capacity of 50,000 pieces

1.Titanium Cnc Parts are made of high-quality materials and processed from high-quality sponge titanium ingots

2.The surface of Titanium Cnc Parts has no peeling cracks, no oil stains and scratches on the surface, and the side section is smooth and clean

3.Titanium Cnc Parts adopts strict process technology, specializing in the research of titanium materials and titanium equipment

Introduction of Titanium Cnc Parts:

Titanium Cnc Parts are high-strength and light-weight, and belong to high-grade metals. They are mainly used in shipbuilding, aerospace, petroleum machinery, energy generation, and medical equipment. Titanium Cnc Parts have good corrosion resistance, low temperature resistance, and high chemical activity.

Parameter information of Titanium Cnc Parts:

Name | Titanium Cnc Parts |

material | Pure titanium, titanium alloy |

Availability | Hot working, cold working, annealing |

Product Category | Titanium cake, titanium ring, titanium square, etc. |

Our processing method:

CNC Milling Processing

1. production machine: CNC machining center, CNC engraving machine, CNC dilling center(3axis. 4axis 5axis)

2. tolerance: +/-0.0005mm

3. surface roughness: Ra 0.4

CNC Turning Processing

1. production machine: CNC turning lathe, automatic lathe,turning-milling machine

2. tolerance: +/-0.0005mm

3. surface roughness: Ra 0.4

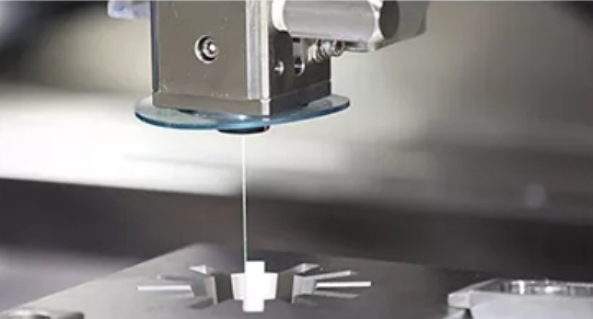

Wire EDM Cutting Processing

1. production machine: WEDM-LS,WEDM-HS

2. tolerance: +/-0 .003mm

3. surface roughness. Ra0.1

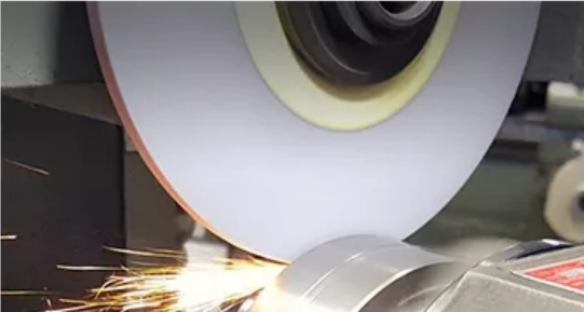

Grinding Processing

1. production machine:surface grinder, cylindrical grinder,

internal grinder

2. tolerance: +/- 0.003mm

3. surface roughness. Ra 0.025

Donggang City Runxin Machinery Co., Ltd. is located in the Yalu River Scenic Area. Founded in 2015, the company covers an area of 8,000 square meters and has 68 employees, including 15 engineers and 8 inspectors. It is a comprehensive service integrating R&D, production, sales and trade. The company is mainly engaged in the custom processing of castings, automobiles and pumps. copper parts. stamping. Industry metal parts cutting and processing, the main machine tools: high-precision CNC lathes, CNC machining center machine tools, improve the processing accuracy and work efficiency of products, ultra-fine precision metal manufacturing and processing, serving high-end domestic and foreign enterprises.