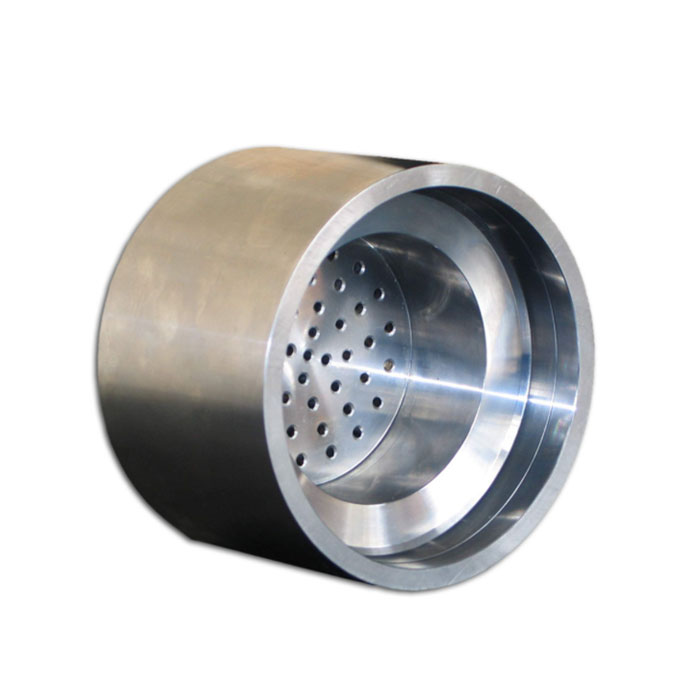

Stainless Steel Flange

Brand Runxin Machinery

Product origin Liaoning, China

Delivery time 1 month

Supply capacity Monthly capacity of 50,000 pieces

1.When Stainless Steel Flange is under pressure, the ribs and lips play the role of strength and sealing respectively, which can not only self-tighten and seal, but also strengthen the pipeline, which greatly strengthens the overall strength of the connection part.

2.Stainless Steel Flange has strong compressive, tensile and bending resistance

Stainless Steel Flange is a disc-shaped part, most common in plumbing engineering, where flanges are used in pairs. In pipeline engineering, flanges are mainly used for the connection of pipelines. In the pipelines that need to be connected, various flanges are installed. Wire flanges can be used for low-pressure pipelines, and welded flanges can be used for pressures above 4 kg. Add a sealing point between the two flanges and fasten them with bolts. Different pressure flanges have different thicknesses and use different bolts. When pumps and valves are connected to pipelines, parts of these equipment are also made into corresponding flange shapes, also known as flange connections.

Product features:

1. Stainless Steel Flange are made of thick and good materials, high hardness, not easy to rust after long-term use

2. Stainless Steel Flange have stable surface treatment, bright appearance and comfortable hand feeling

3. Various product specifications, large inventory, can be customized according to customer requirements

4. Suitable for oil pipelines, shipbuilding industry, chemical industry, construction industry and steel structure industry, etc.

Product parameters:

Product Specifications | CNC machining |

Processing material | Stainless steel |

Precision | finishing |

Processing cycle | 10 days |

surface treatment | Grinding, polishing, deburring, oxidation, sandblasting |

Our advantages and services;

Our top priorities are quality, speed and on-time delivery. We take these values very seriously because our customers are the most important part of our business. We want every customer to see us as a valued manufacturing partner for their design, prototyping and/or long-term production needs. For every client, we go through the following process to ensure the highest level of quality service:

1. Thoroughly evaluate your project and part design, and work directly with you if we recommend any design adjustments to your machined or 3D printed part to ensure its manufacturability.

2 Send professional interactive quotes directly to your email through our TAR compliant paperless parts quote platform.

3. Use optimized manufacturing methods, material selections and specified tolerances to produce your parts,

4. Check your parts after all manufacturing and finishing processes to verify tolerances and quality.

5. Deliver your parts on time according to the delivery time you choose.

6. Contact the car after you receive the zero to ensure we provide the highest level of service.

If we find any discrepancies in maintaining our quality standards and on-time delivery during this process, we will seek solutions immediately.

document preparation:

We use the best file data, build preparation, CAD and CAM software to Evaluate, and if necessary repair, edit and design your machining or 3D printing parts and assemblies to meet your desired specifications.

surface analysis:

With our industrial printer laser inspection software, we can scan and adjust for micron scan point deviation throughout the printing process and provide print quality reports for your 3D printed parts.

Overview of the company's equipment, South Korea's Hyundai Wia, Doosan Machine Tool. Horizontal machining center with very high precision.